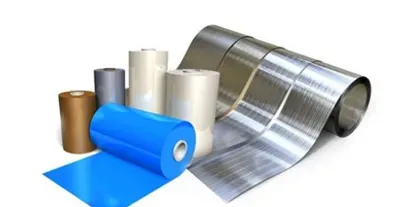

- PET Release Film

- R-PET Film with PCR

- Ultra-clear BOPET Film

- White/ Matte BOPET Film

- UV Stabilized PET Film

- Heat Resistant PET Film

- High Shrink BOPP Cigarette Film

- BOPP Heat Sealable Film

- BOPP Tear Tape Film

- BOPP Holographic Substrate Film

- BOPP Pearl White Film

- BOPP Synthetic Paper

- BOPP Matte Transfer Film

- Chemically Coated Clear Film (1/2 Sides)

- Chemically Coated White Film

- Bright White Metallized PET Film

- Anti-Static BOPET Film

- Anti-Fog Film

- High Gloss Metallized PET Film

- Matte Metallized PET Film

- High Gloss Metallized BOPP Film

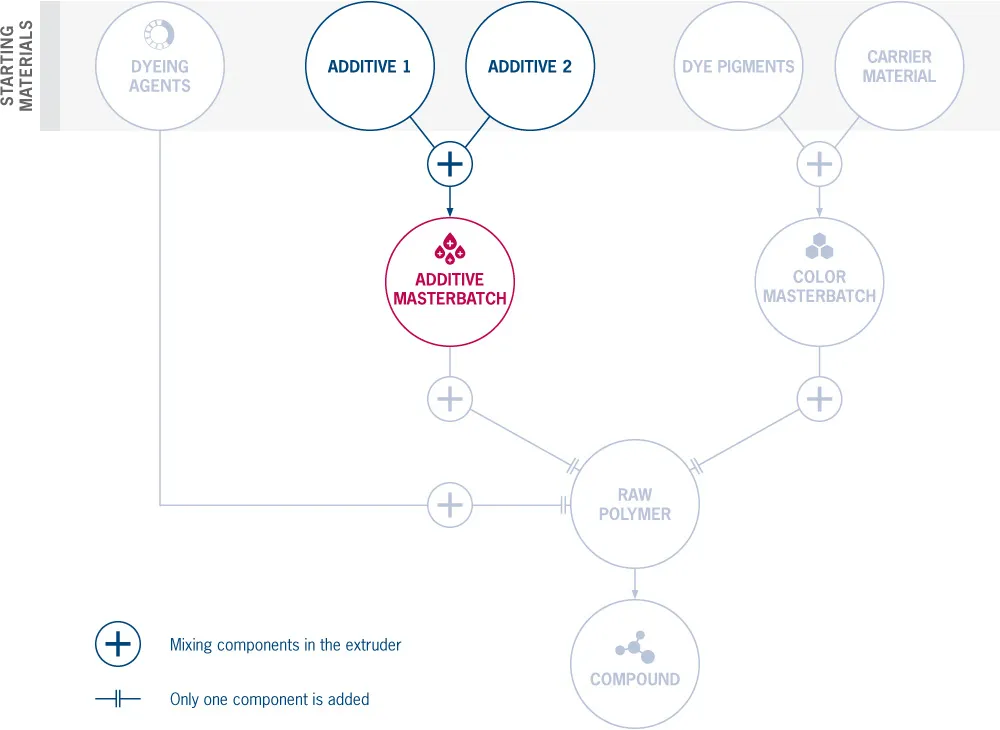

PLASTIC CONCENTRATE WITH FUNCTION

Jindal is specialised in precisely modifying the properties of polymers. Depending on the use case, we create concentrates for conditioning plastics with functions such as light resistance, heat resistance, anti-oxidation or anti-static properties. This is how additive masterbatches like the UV-masterbatch are made. Likewise, it is possible to condition plastics to act as lubricants, demoulding elements and propellants. Just contact with us in order to discuss the requirements for your additive masterbatch.

Flexible & Rigid Packaging

Laser marking – The fast solution for labelling plastics

We offer high-tech solutions for the foods industry

An additive masterbatch is a concentrate in granule form for modifying thermoplastics. Additive masterbatches consist of one or more additives and a polymer-specific carrier resin.

Additive masterbatches may, for example, contain the following additives:

- Stiffener M/B

- Antistatic slip M/B

- Antistatic M/B

- Slip and Antiblock M/B

- Anti-aging M/B

- Matte M/B

- Matte Transfer M/B

- High transmittance M/B

WANT TO ADD VALUE TO YOUR PRODUCTS?

Jindal Film Materials offers over 30 years of film manufacturing expertise and creativity. In addition to high-quality standard references, the largest part of the our product range consists of customized references. This enables us to enhance the individuality of the customers’ products.